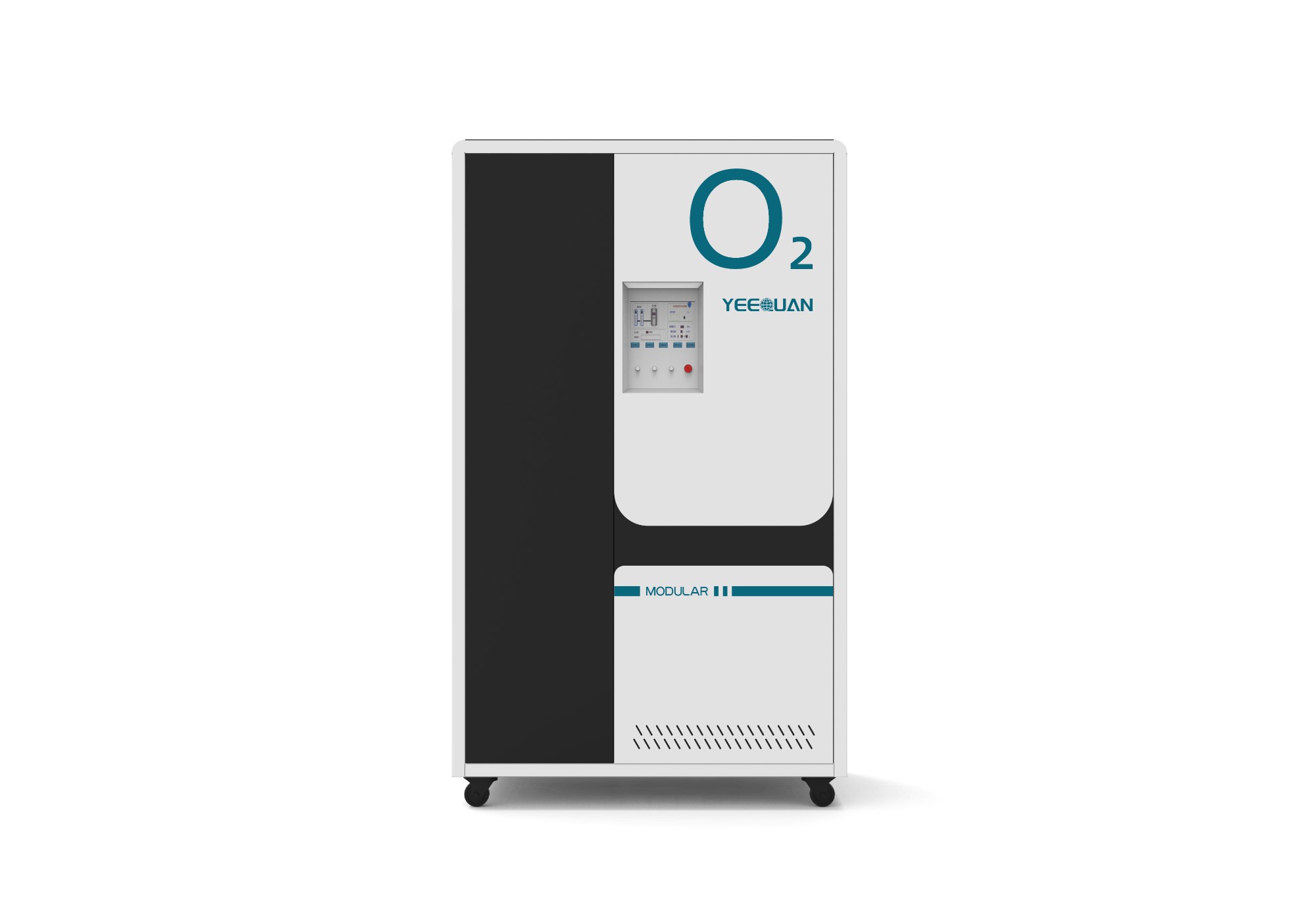

High Pressure Oxygen Generator 5.0-50m³/hr

High Pressure Oxygen Generator

Main Technical Parameter

Model | Oxygen Flow (m³/h) | Outlet pressure (Mpa) | Dimention (mm) | Power/Voltage (Kw/VA) | O2 storage tank (L) |

YQ-3.0-P | 3 | 0.7 | 950x750x1660 | 3.9/380 | 600 |

YQ-5.0-P | 5 | 0.7 | 950x750x1660 | 5.8/380 | 600 |

YQ-10.0-P | 10 | 0.7 | 1170x750x1990 | 11.2/380 | 1000 |

YQ-20.0-P | 20 | 0.7 | (1170x750x1990)x2 | 22/380 | 3000 |

YQ-30.0-P | 30 | 0.7 | (1170x750x1990)x3 | 33/380 | 4000 |

YQ-40.0-P | 40 | 0.7 | (1170x750x1990)x4 | 44/380 | 5000 |

YQ-50.0-P | 50 | 0.7 | (1170x750x1990)x5 | 55/380 | 6000 |

Note: Oxygen storage tank outside, which can be configured according to the actual situation. Please follow to the actual oxygen consumption of the hospital.

Features:

1. Modular Design: Independent module operation with fault isolation.

2. Oil-Free Scroll Variable-Frequency Air Compressor: Low maintenance, energy-efficient, and high-performance.

3. Lithium-Based Molecular Sieve: High adsorption rate, stable, and long-lasting.

4. Proprietary Oxygen Separation Process: Achieves >90% oxygen concentration within 3 minutes of startup.

5. Max.output pressure up to 0.7Mpa/7 bar.

6. Energy Efficiency: 1 m³ of oxygen per 1 kWh (P).

Application:

1. Medical and health sector

Hospital centralised oxygen supply system:

Used in ICU, operating theatre, emergency department, etc. to meet the demand of high flow and high purity oxygen.

Replace traditional oxygen cylinders and reduce operation cost.

Home Oxygen Therapy:

Provide long-term oxygen therapy support for patients with chronic obstructive pulmonary disease (COPD), pulmonary fibrosis, etc.

Oxygen supply in plateau area:

Suitable for plateau medical institutions, military stations or hotels to relieve plateau reaction.

2. Industrial field

Metal smelting and cutting:

Oxygen-enriched combustion: Increase furnace temperature (e.g. electric furnace steelmaking, glass melting furnace), reduce fuel consumption by 20%~30%.

Oxyacetylene cutting: support high precision metal processing.

Chemical & Petrochemical:

Used for oxidation reaction (e.g. ethylene production, waste water treatment), catalyst regeneration, etc.

Paper & Bleaching:

Replace chlorine bleaching, environmentally friendly and efficient (ECF elemental chlorine-free bleaching process).

3. Environmental protection and energy

Wastewater Treatment:

Aeration and Oxygenation: Enhance the efficiency of wastewater treatment (e.g. activated sludge method), especially suitable for high concentration organic wastewater.

Ozone generator supporting:

Provide high purity oxygen to generate ozone for drinking water disinfection and industrial wastewater treatment.

Oxyfuel combustion for emission reduction:

Oxyfuel combustion in power plants or boilers to reduce NOx and CO₂ emissions.

4. Other special applications

Aquaculture:

Oxygen enhancement to improve aquaculture density (e.g. shrimp, salmon farming), to avoid fish hypoxia.

Aerospace & Diving:

Provide emergency oxygen supply for confined space (e.g. submarine, spacecraft).

Laboratory & Research:

Experiments requiring high purity oxygen (e.g. fuel cell testing, material synthesis).

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Sunny He

Phone: 86-18830788871

Tel: 18830788871

Email: marketing@yeequanmed.com

Add: Block C, Diangu Yuansheng Plaza, No. 1898, Chaoyang North Street, Gaokai District, Baoding City, Hebei Province